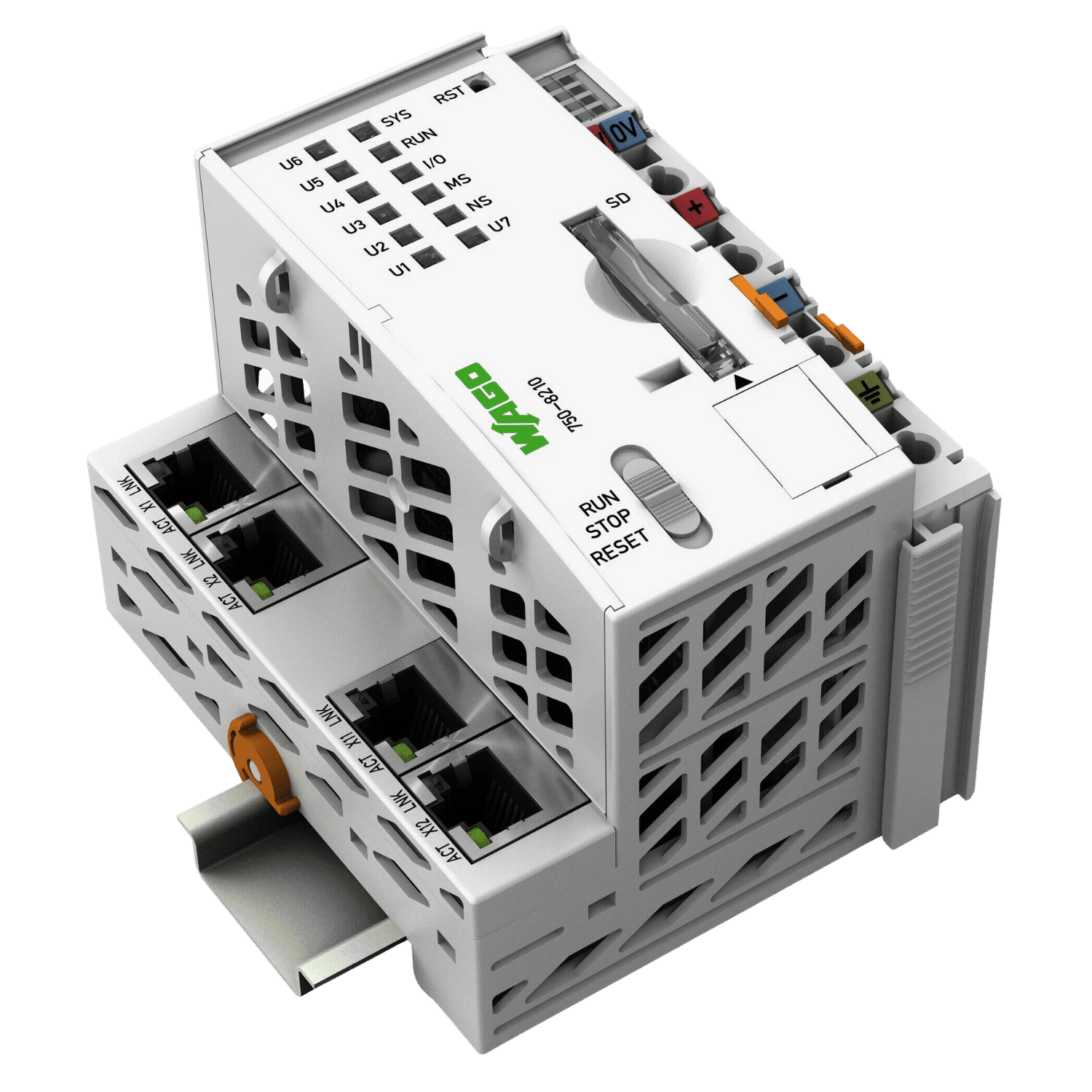

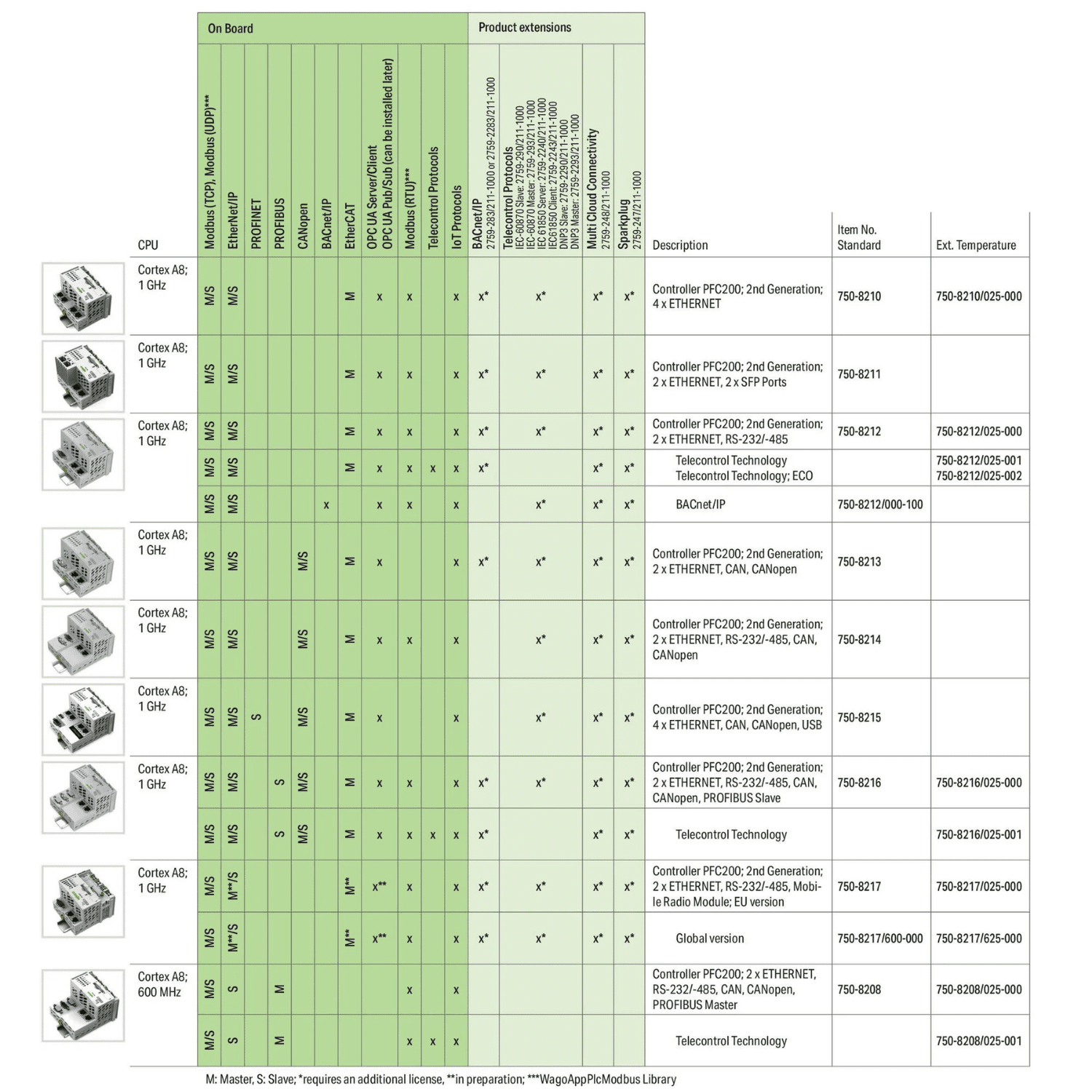

The PFC200 Controller is a compact PLC for the modular WAGO I/O System. Besides network and fieldbus interfaces, the controller supports all digital, analog and specialty modules found within the 750/753 Series.

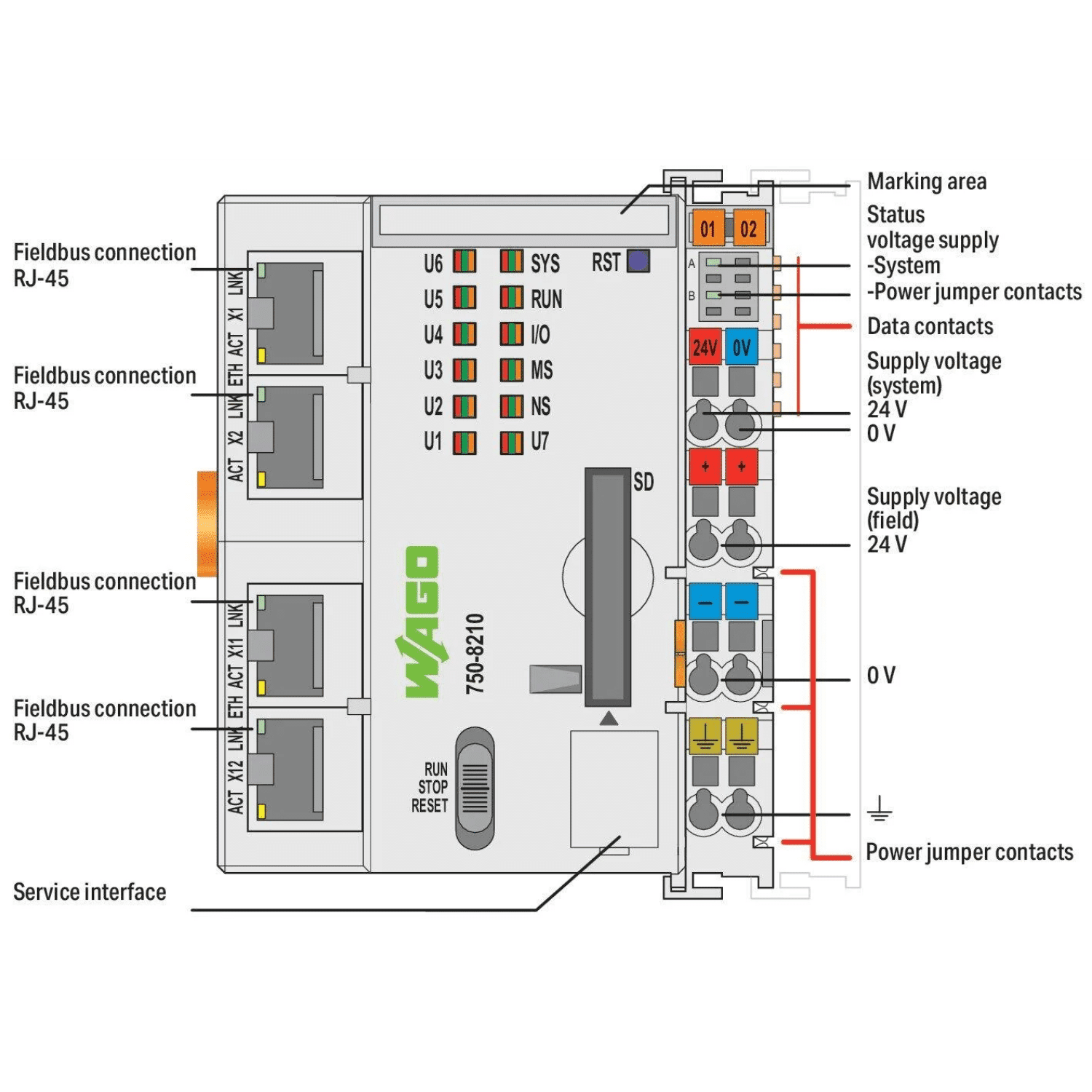

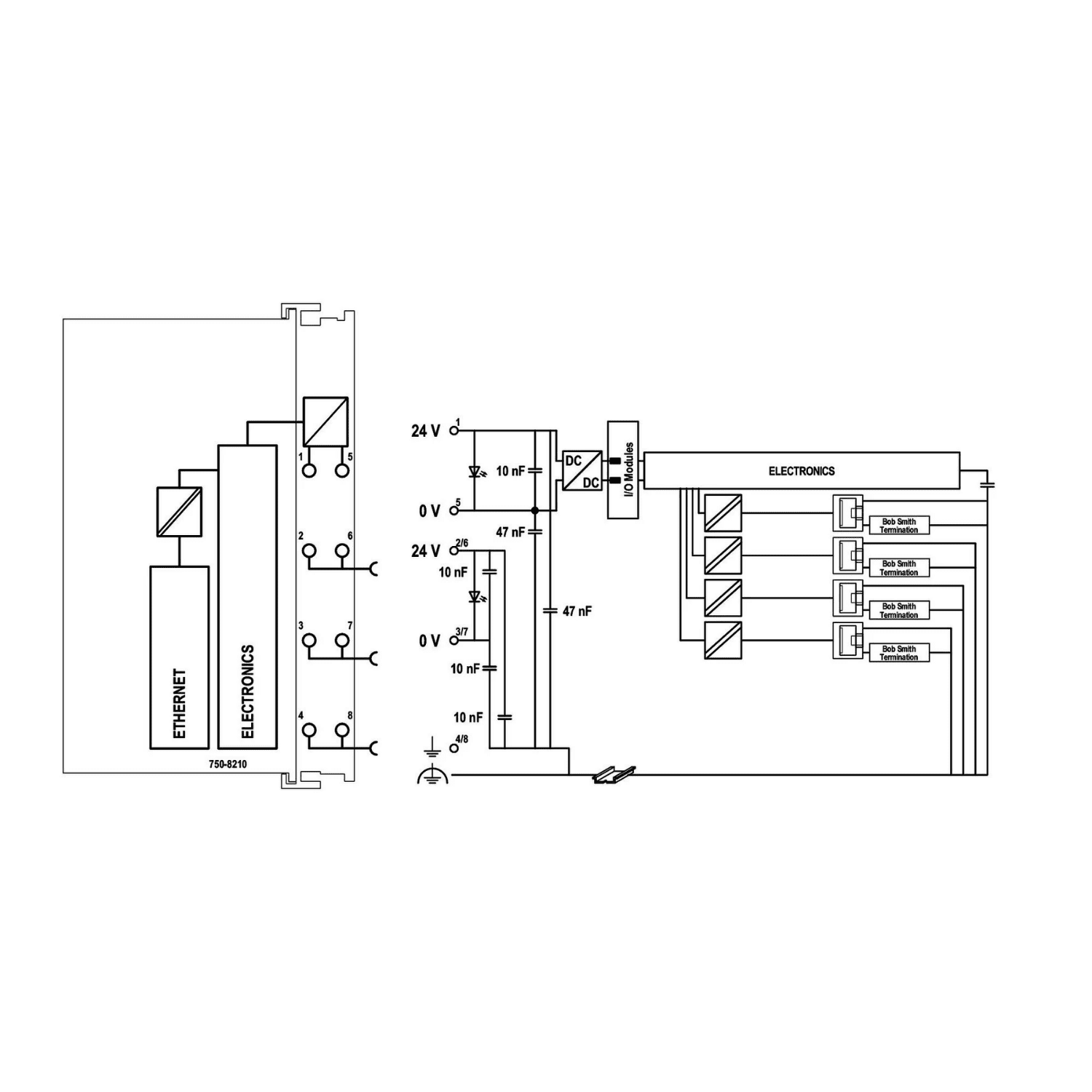

Four ETHERNET interfaces and an integrated switch enable line topology wiring.

An integrated Webserver provides user configuration options, while displaying PFC200 status information.

Besides the processing industry and building automation, typical applications for the PFC200 include standard machinery and equipment control (e.g., packaging, bottling and manufacturing systems, as well as textile, metal and wood processing machines).

Advantages:

- Programming per IEC 61131-3

- Programmable with CODESYS V3.5 from Firmware Release 23, WAGO-I/O-PRO V2.3 or e!COCKPIT up to Firmware Release 22

- Direct connection of WAGO's I/O modules

- 4 x ETHERNET (configurable)

- Linux® operating system with RT‐Preempt patch

- Configuration via CODESYS, e!COCKPIT or Web-Based Management user interface

- Maintenance-free

Technical data

| Communication | Modbus TCP master/slave Modbus (UDP), WagoAppPlcModbus Library Modbus (RTU), WagoAppPlcModbus Library ETHERNET EtherNet/IPTM Adapter (slave) EtherNet/IPTM Scanner EtherCAT® Master OPC UA Server/Client OPC UA Pub/Sub (can be installed later) MQTT BACnet/IP, requires an additional license Telecontrol protocols, requires an additional license |

| ETHERNET protocols | DHCP DNS NTP FTP FTPS SNMP HTTP HTTPS SSH |

| Telecontrol protocols | IEC 60870 (additional license as slave or master) IEC 61850 (additional license as Client or Server) DNP3 (additional license as Slave or Master) IEC 60870-5-101/-103/-104 (additional license as slave or master) IEC-61850 (additional license as Client 300) DNP3 (additional license as Slave or Master 300) IEC 60870-5-101/-103/-104 (Zusatzlizenz als Slave oder Master) IEC-61850 (Zusatzlizenz als Client 300) DNP3 (Zusatzlizenz als Slave oder Master 300) |

| Visualization | Web-Visu Web Visu |

| Operating system | Real-time Linux (with RT-Preempt patch) |

| CPU | Cortex A8; 1 GHz |

| Programming languages per IEC 61131-3 | Instruction List (IL) Ladder Diagram (LD) Function Block Diagram (FBD) Continuous Function Chart (CFC) Structured Text (ST) Sequential Function Chart (SFC) |

| Programming environment | CODESYS V3.5, Firmware Release 23 or higher e!COCKPIT (based on CODESYS V3) up to Firmware Release 22 WAGO-I/O-PRO V2.3 (based on CODESYS V2.3), up to Firmware Release 22 |

| Configuration options | CODESYS V3 e!COCKPIT WAGO-I/O-CHECK Web-Based Management e!RUNTIME library CODESYS Library |

| Baud rate (communication/fieldbus 1) | 10/100 Mbit/s |

| Baud rate | ETHERNET: 10/100 Mbit/s |

| Transmission medium (communication/fieldbus) | ETHERNET: Twisted Pair S-UTP; 100 Ω; Cat. 5; 100 m maximum cable length |

| Main memory (RAM) | 512MB |

| Internal memory (flash) | 4096MB |

| Non-volatile hardware memory | 128kbyte |

| Program memory | CODESYS V2: 16 MB; CODESYS V3: 32 MB |

| Data memory | CODESYS V2: 64 MB; CODESYS V3: 128 MB |

| Non-volatile software memory | 128kbyte |

| Non-volatile software memory | 128.kbyte |

| Type of memory card | SD and SDHC up to 32 GB (all guaranteed properties only valid with WAGO's memory card) |

| Memory card slot | Push-push mechanism; Cover lid (sealable) |

| Number of modules per node (max.) | 250 |

| Number of modules without a bus extension (max.) | 64 |

| Input and output process image (internal) max. | 1000 words/1000 words |

| Input and output process image (fieldbus) max. | CODESYS V2: 1000 words/1000 words; CODESYS V3: 32000 words/32000 words |

| Indicators | LED (SYS, RUN, I/O, U1 … U7) red/green/orange: Status of system, program, local data bus, status programmable by user (can be used via CODESYS library); LED (A, C) green: Status of system power supply, field supply |

| Supply voltage (system) | 24 VDC (-25 … +30 %); via pluggable connector (CAGE CLAMP® connection) |

| Input current (typ.) at nominal load (24 V) | 550mA |

| Total current (system supply) | 1,700mA |

| Supply voltage (field) | 24 VDC (-25 … +30 %); via power jumper contacts |

| Current carrying capacity (power jumper contacts) | 10A |

| Number of outgoing power jumper contacts | 3 |

| Isolation | 500 V system/field |

Connection data

| Connection technology: communication/fieldbus | Modbus (TCP, UDP): 4 x RJ-45 |

| Connection technology: system supply | 2 x CAGE CLAMP® |

| Connection technology: field supply | 6 x CAGE CLAMP® |

| Connection type 1 | System/field supply |

| Solid conductor | 0.08 … 2.5 mm² / 28 … 14 AWG |

| Fine-stranded conductor | 0.08 … 2.5 mm² / 28 … 14 AWG |

| Strip length | 8 … 9 mm / 0.31 … 0.35 inches |

| Connection technology: device configuration | 1 x Male connector; 4-pole |

Physical data

| Width | 78.6 mm / 3.094 inches |

| Height | 100 mm / 3.937 inches |

| Depth | 71.9 mm / 2.831 inches |

| Depth | 64.7 mm / 2.547 inches |

Mechanical Data

| Weight | 215.4g |

| Color | light gray |

| Housing material | Polycarbonate; polyamide 6.6 |

| Conformity marking | CE |

Environmental requirements

| Ambient temperature (operation) | 0 … +55 °C |

| Ambient temperature (storage) | -25 … +85 °C |

| Protection type | IP20 |

| Pollution degree | 2 per IEC 61131-2 |

| Operating altitude | without temperature derating: 0 … 2000 m; with temperature derating: 2000 … 5000 m (0.5 K/100 m); 5000 m (max.) |

| Relative humidity (without condensation) | 95% |

| Mounting position | any |

| Mounting type | DIN-35 rail |

| Vibration resistance | 4g per IEC 60068-2-6 |

| Shock resistance | 15g per IEC 60068-2-27 |

| EMC immunity to interference | per EN 61000-6-2, marine applications |

| EMC emission of interference | per EN 61000-6-3, marine applications |

| Exposure to pollutants | per IEC 60068-2-42 and IEC 60068-2-43 |

| Fire load | 2.544MJ |

| Permissible H2S contaminant concentration at a relative humidity 75 % | 10ppm |

| Permissible SO2 contaminant concentration at a relative humidity 75 % | 25ppm |

Commercial data

| ETIM 8.0 | EC000236 |

| ETIM 8.0 | EC000236 |

| PU (SPU) | 1 pcs |

| Packaging type | BOX |

| Country of origin | DE |

| GTIN | 4055143981378 |

| Customs tariff number | 85371091990 |

Additional information

| Brand |

|---|

Reviews

There are no reviews yet.