TeSys LE

Enclosed direct-on-line and star-delta starters, for motors up to 80 A (37 kW / 400 V) – DOL starter

Part of TeSys

Features

TeSys LE enclosed starters come in multiple solutions

D.O.L. starters

- LE1, LE2 range: contactor + overload Rrelay Up to 37 KW

- Available in both reversing and non-reversing starters

- Conforms to standards IEC 60947-4-1

- IP 65 degree of protection

- Ambient air temperature: operation from -5 to +40 C

- For supply voltages between 380 and 440 V. Control circuit is pre-wired between phases. For any other supply voltages, the control circuit must be wired by the customer

- Overload relay must be ordered separately except LE1M pre-configured range

- Operating positions: similar to contactors

- Enclosure Material: LE2 K and LE D09-D35 in Polycarbonate, LE D40A-D65A in Sheet Steel

D.O.L. starters with fuse disconnecting switch

- Direct on-line LE4, LE8 range fuse switch-disconnector + contactor + overload relay Up to 15 kW

- Available in both reversing and non-reversing starters

- Conforms to standards IEC 60947-4-1

- IP 65 degree of protection

- Ambient air temperature: Operation from -5 to +40 C

- For supply voltages between 380 and 440 V. Control circuit is pre-wired between phases. For other supply voltages, the control circuit must be wired by the customer

- Overload relay must be ordered separately, same as for fuse.

- Enclosure material: Polycarbonate

D.O.L starters enclosure for thermal magnetic circuit breaker and contactor

- LE1GV Enclosure for thermal magnetic circuit breaker + contactor Up to 5.5 kW

- Conforms to standards IEC 60947-4-1

- IP 55 degree of protection

- Material: Polycarbonate

Star-delta starters

- Star-delta LE3 range contactors + overload relay Up to 30 kW

- Conforms to standards IEC 60947-4-1

- IP 65 degree of protection

- For supply voltages between 380 and 415 V. Control circuit is pre-wired between phases. For any other supply voltages, the control circuit must be wired by the customer

- Overload relay must be ordered separately

- Material: Polycarbonate

Replacement parts are available

Benefits

TeSys LE Enclosed motor starter provides flexible installation for local motor control in a harsh environment exposed to dust, vaper and water jet.

- Easy and quick installation

- Pre-wired circuit

- DIN Rail installed for product mounting

- Cable entry easy access

- IP 65 degree of protection in harsh conditions

- Continuous service thanks to coordination

Applications

TeSys LE can be used for all type of applications across industry, infrastructure and buildings, and machines requiring:

- DOL motor starting or stopping

- Reverse/Non-reverse starting

- Simple soft starting

Overload protection with/without isolating device

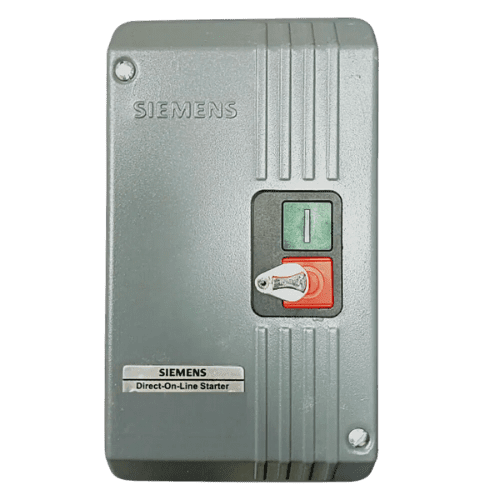

Siemens DOL Starter Switches

- Starter in sheet steel housing, incl. birelay with SPP

- Motor rating at 415V | 3 phase | 50Hz

Features of DOL Starter

- High starting current.

- High starting torque.

- Voltages dip in the power mains.

- Simplest controlling mechanism.

- Suitable for low power rated motor.

Uses

- DOL Starters are best suited for low power rated motors.

- Applied where the starting current poses no threat to the windings of the motor.

- Applied where the starting current does not result in a huge dip in the line voltage.

- For small water pumps.

- For conveyor belts.

- For fans.

- For compressors.

Working

The basis of the working principle in the DOL Starter is the connection to the 3-phase main with the induction motor. The control circuit is energized in any two phases. On pressing the start switch, the current starts flowing through the contactor coil and the control circuit. As the current energizes the contactor coil, a 3-phase supply is available to the motor. Now when we press the stop switch, current stops flowing through the contact, and supply to the induction motor is discontinued. As the supply breaks, the machine comes to rest.

Construction

In the DOL Starter, there are two switches- Green and Red. The Green switch is for starting and the Red switch is for stopping the motor. For the protection of the motor, there are circuit breakers, overload relay, and contactor. The contacts are controlled by the two switches of the motor. To start the motor, the Green switch is pressed and the full-line voltage starts coming out to the induction motor. In general, the contactors are 3-pole or 4-pole. For example, three normally open contacts and one auxiliary are present in 4-pole type contactors. The normally open contacts connect the induction motor to supply lines and the auxiliary contact is used for boosting the contactor coil when the start switch is pressed. In case of any fault, the holds on the contactor get deactivated and the motor supply is discontinued.

Wiring

The DOL Starter wiring comprises of four parts- main contact, normally open contacts, normally closed contacts, and the connections of the relay coil and the thermal overload relay.