The hardware or software that allows a user to communicate with a controller. A physical control panel with buttons and indicator lights can be an HMI, as can an industrial Computer with a colour graphics display running HMI software.

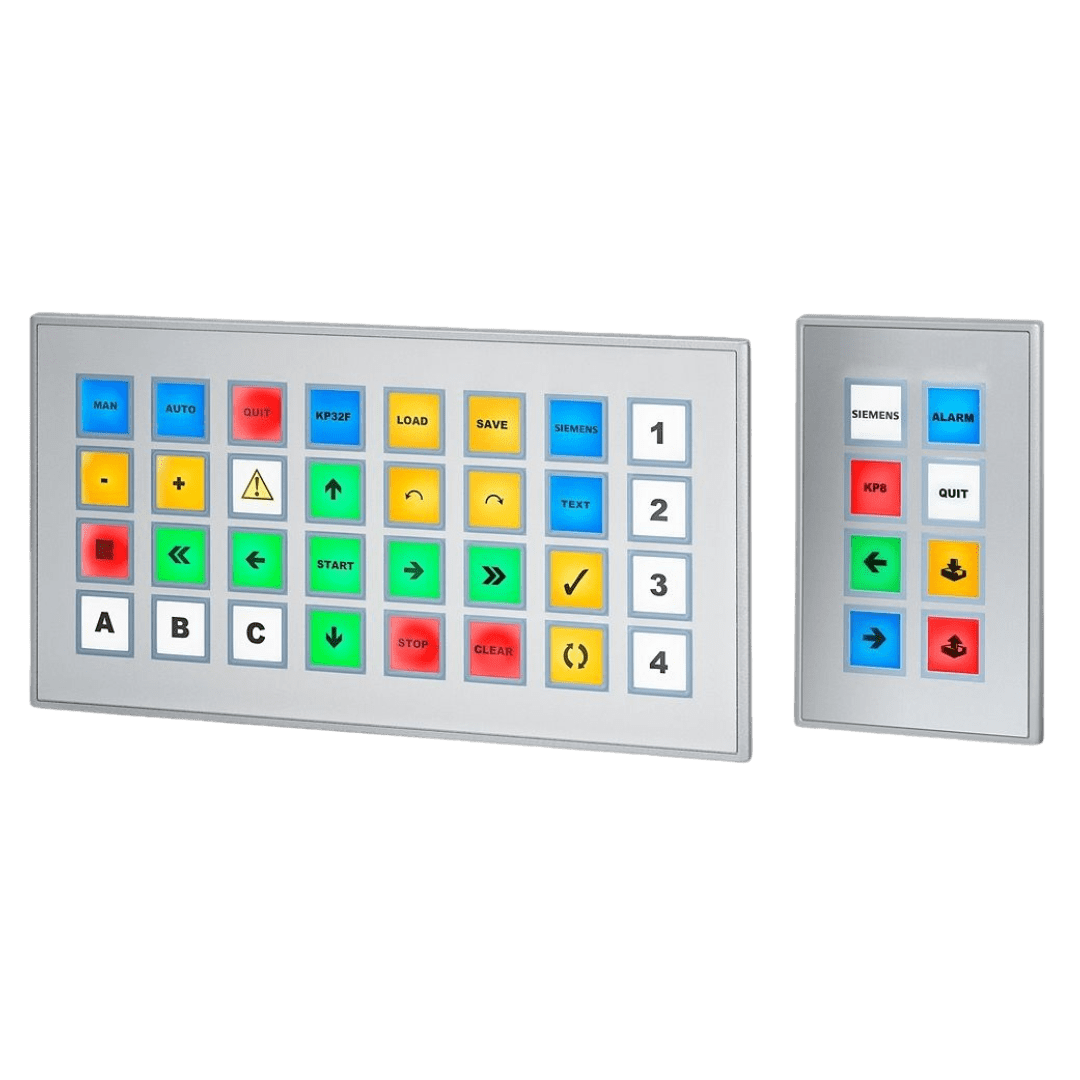

Key Panels

SIMATIC HMI Key Panels put an end to hard-wired, time-consuming, error-prone, and individually mounted operator controls. These prefabricated, ready-to-install key panels cost-effectively combine numerous basic functions, thus reducing configuration and installation costs by up to 80 percent. Material costs are also lowered . The compact, rugged, and easy-to-install SIMATIC HMI Key Panels provide two PROFINET-capable Ethernet interfaces, can display five event-driven colors (red, green, blue, white, yellow), and are impressive with their flexibility.

View Technical Data

Comfort Panels

Powerful SIMATIC HMI Comfort Panels are the High-end operator panels for sophisticated HMI applications. They were designed for implementing more complex visualization tasks on the machine level. They offer maximum convenience in high-end applications thanks to their top performance, functionality, and numerous integrated interfaces. The portfolio includes a series of versions for special use cases such as IP65-protected PRO devices, panels with a stainless-steel front, outdoor versions, and specially hardened SIPLUS versions.

View Technical Data

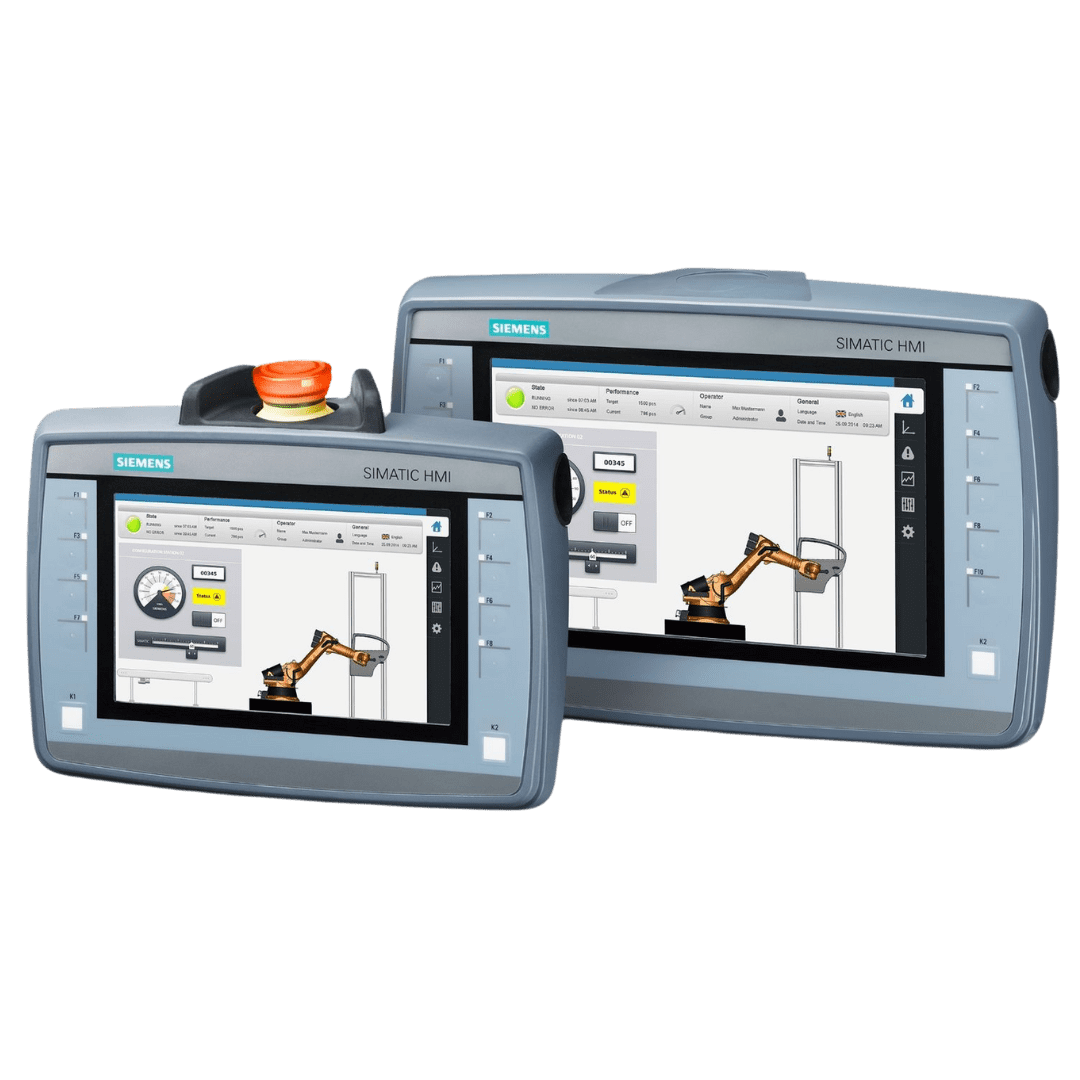

Mobile Panels

Harness the dual benefits of power and safety with SIMATIC HMI Mobile Panels from Siemens, specially engineered for your high-end applications and fail-safe machinery. These portable operator panels bring the advanced features and high performance of SIMATIC HMI Comfort Panels to your fingertips, enhancing operational flexibility and user convenience in even the most complex, distributed plant setups. By integrating these mobile panels, you gain the advantage of mobility without sacrificing performance or operational security.

View Technical Data

PC Based HMI

PC-based systems are the go-to choice for managing complex HMI tasks in production environments that demand high-level information processing and documentation. They offer robust storage and processing capabilities, along with versatile data connectivity options. Users can opt for a centralized system, which merges the PC and visualization unit, or a decentralized approach with an industrial monitor or thin client. Siemens also provides tailored solutions for extreme conditions and integrates SIMATIC IPCs into their HMI operator panels.

For more Information About SIMATIC HMI Basic Panels

SIMATIC HMI Basic Panels

Cost-effective operation and monitoring in the 2nd Generation

With their sophisticated HMI basic functions, SIMATIC HMI Basic Panels 2nd generation is the ideal entry-level series for simple HMI applications. The device series offers panels with 4″, 7″, 9″ and 12″ displays, and combined key or touch operation The innovative widescreen displays are high resolution with 64,000 colors. They can be installed in portrait mode and are especially energy-efficient due to their 100% dimmable brightness. The innovative user interface opens up a wide range of operations with improved usability through new controls and graphics. The USB interface allows you to connect a keyboard, mouse and barcode scanner and supports easy archiving of data on a USB stick.

The HMI Basic Panels 2nd Generation at a glance

• Ideal entry-level range for simple HMI applications

• Engineered in the TIA Portal

• Mounting compatibility with SIMATIC HMI Comfort Panels and existing SIMATIC HMI Basic Panels 4“ and 6“

• Flexible scalability within the HMI range

• High-resolution, dimmable wide-screen displays with 64.000 colors

• Innovative user interface and improved usability thanks to new controls and graphics

• Touch/key functionality for intuitive operation

• Interface for connection with various PLCs

• Versions for PROFIBUS or PROFINET

• Archiving via USB stick

Improved process quality

Scalable Software for easy configuration

High-resolution wide-screen displays

Improved usability

SIMATIC HMI Comfort Panels

High-end operator devices for sophisticated HMI applications

SIMATIC HMI Comfort Panels are designed for the implementation of high-performance visualization applications on the machine level. High performance, functionality and numerous integrated interfaces offer the greatest convenience in high-end applications. SIMATIC HMI Comfort Panels Standard devices form the technological basis for specialised variants like IP65-protected devices, panels with a stainless steel front, or outdoor applications as well as coated versions.

Brilliant, intelligent and practical

SIMATIC HMI Comfort Panels are designed for the implementation of high-performance visualization applications on the machine level. High performance, functionality and numerous integrated interfaces offer the greatest convenience in high-end applications.

The SIMATIC HMI Comfort Panels are the first choice for solving complex HMI applications.

They feature state-of-the-art technology, outstanding performance as well as integrated functionality and come in high-quality aluminium fronts from size 7” or larger.

SIMATIC HMI Comfort Panels are seamlessly integrated into the TIA Portal via WinCC. This innovative engineering framework represents the key to the full performance capabilities of Totally Integrated Automation

Brilliant

Brilliant displays in widescreen format

- Up to 40%, larger visualization area than conventional displays: Complex operating screens can also be displayed and divided into sections for application control and application monitoring.

- The high resolution, 16 million colors, and a wide viewing angle of up to 170° allow optimal readability and a detailed process display

- Minimized energy demand and maximized display service life: The brightness of the LED backlight can be dimmed by up to 100% to adapt to the lighting conditions of the application.

- The Comfort Panels which were the first widescreen SIMATIC product family received the well-known iF product design award in 2012.

Intelligent

Energy efficiency due to PROFIenergy

- PROFIenergy actively controls the current consumption of all automation components

- Disconnection of individual loads or entire production units when they are not required

- Coordinated switching ensures a high degree of plant reliability

- Continuous investment protection through easy integration into existing standards

Maximum data security if power fails

- In case of a power failure, Comfort Panels buffer sufficient energy to correctly terminate all active archives and to back up the data already archived in RDB format. This ensures the retention of all data in the archive in a cost-efficient manner and without the use of a maintenance-intensive battery.

- To fully ensure the retention of individual, not yet archived data, the use of an uninterruptible power supply unit is recommended

Precise diagnostics made easy

- Increased plant availability

- When connected to SIMATIC Controllers, diagnostic information can be read out directly via the Comfort Panel

- Cost savings – no additional diagnostic hardware is required

Practical

Easy to operate

- Intuitive, fast entries due to familiar and easy-to-operate operator control similar to that of a mobile phone keypad

- Eased user guidance thanks to function keys with LEDs

- Additional operating reliability through tactile feedback of all keys – for example, important when working with gloves

More interfaces – fewer hardware costs

- Easy integration in existing system structures and networks thanks to PROFIBUS and PROFINET standard interfaces

– From 7“ device upwards: 2 PROFINET interfaces with integrated network switch

– From 15“ upwards: Additional third PROFINET interface - Audio In/Audio Out interface for playback of sound files via integrated Media Player

- Easy connection of external devices (printers, USB flash drives, mouse, keyboard, etc.) via 2 integrated USB host interfaces

Optimum convenience during commissioning and servicing

- Simple download of projects via low-cost standard cables.

- All Ethernet settings can already be made during the configuration

- Continuously saved device image the through automatic backup of all data on SD card

- Simple transfer of panel data to replacement device: Replug SD card – confirm – get going

Basic Model

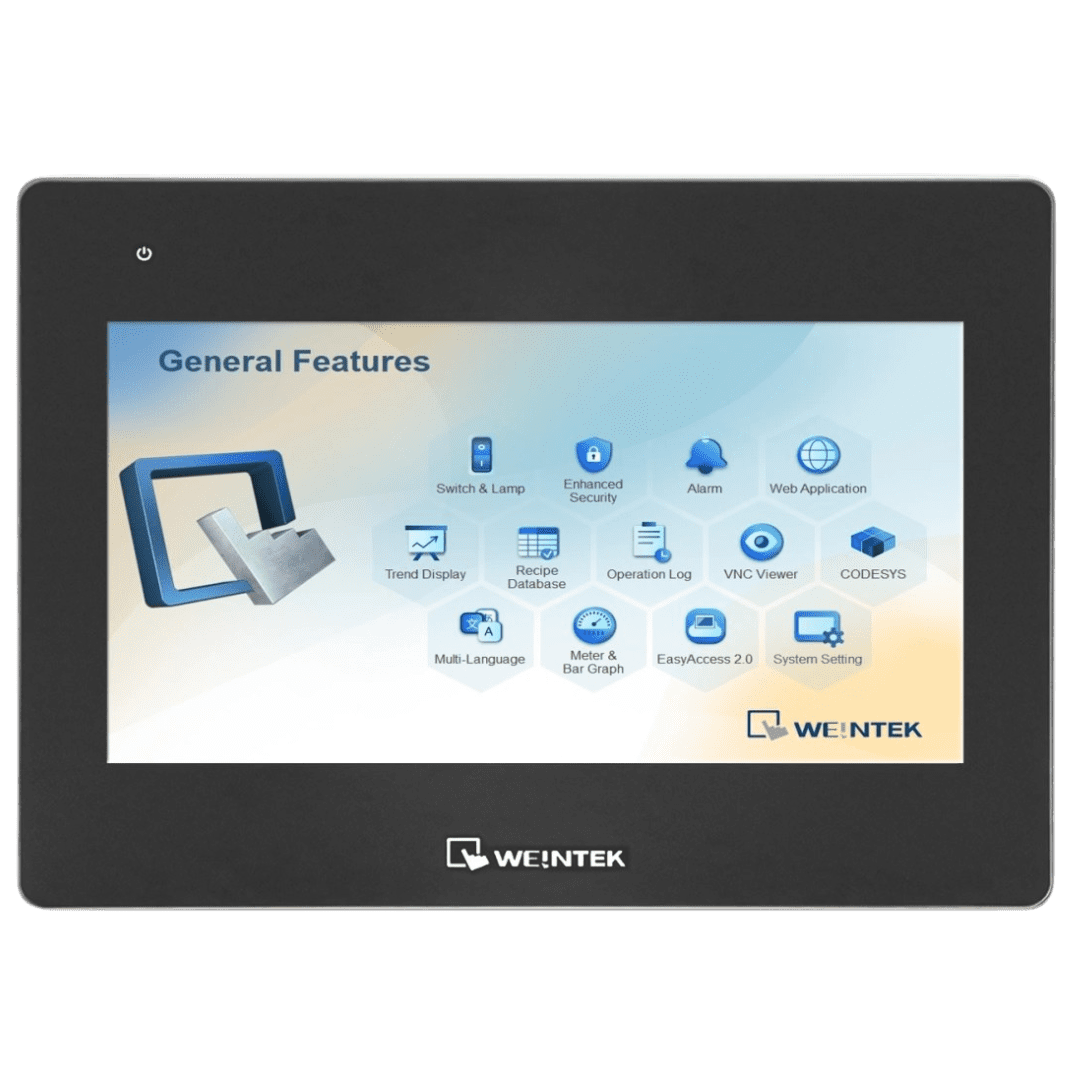

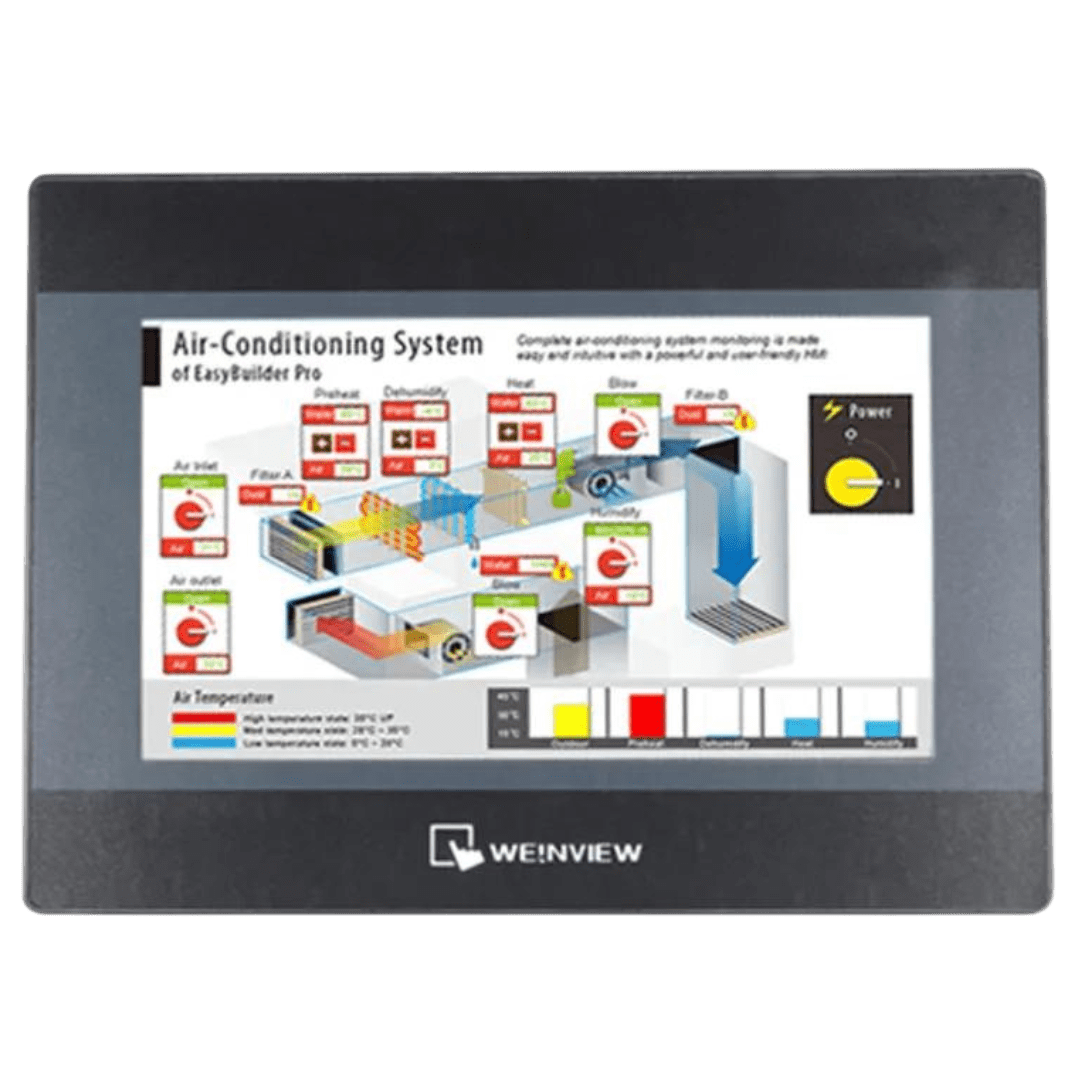

The Weintek basic model HMI (Human Machine Interface) provides an intuitive and user-friendly interface for machine control and monitoring. These HMIs typically feature high-resolution TFT color touch screens, support for multiple communication protocols, and easy-to-use development software. They are equipped with durable hardware designed for industrial environments, and often include features like data logging, recipe management, and alarm handling, making them versatile for a wide range of automation applications.

View Broucher

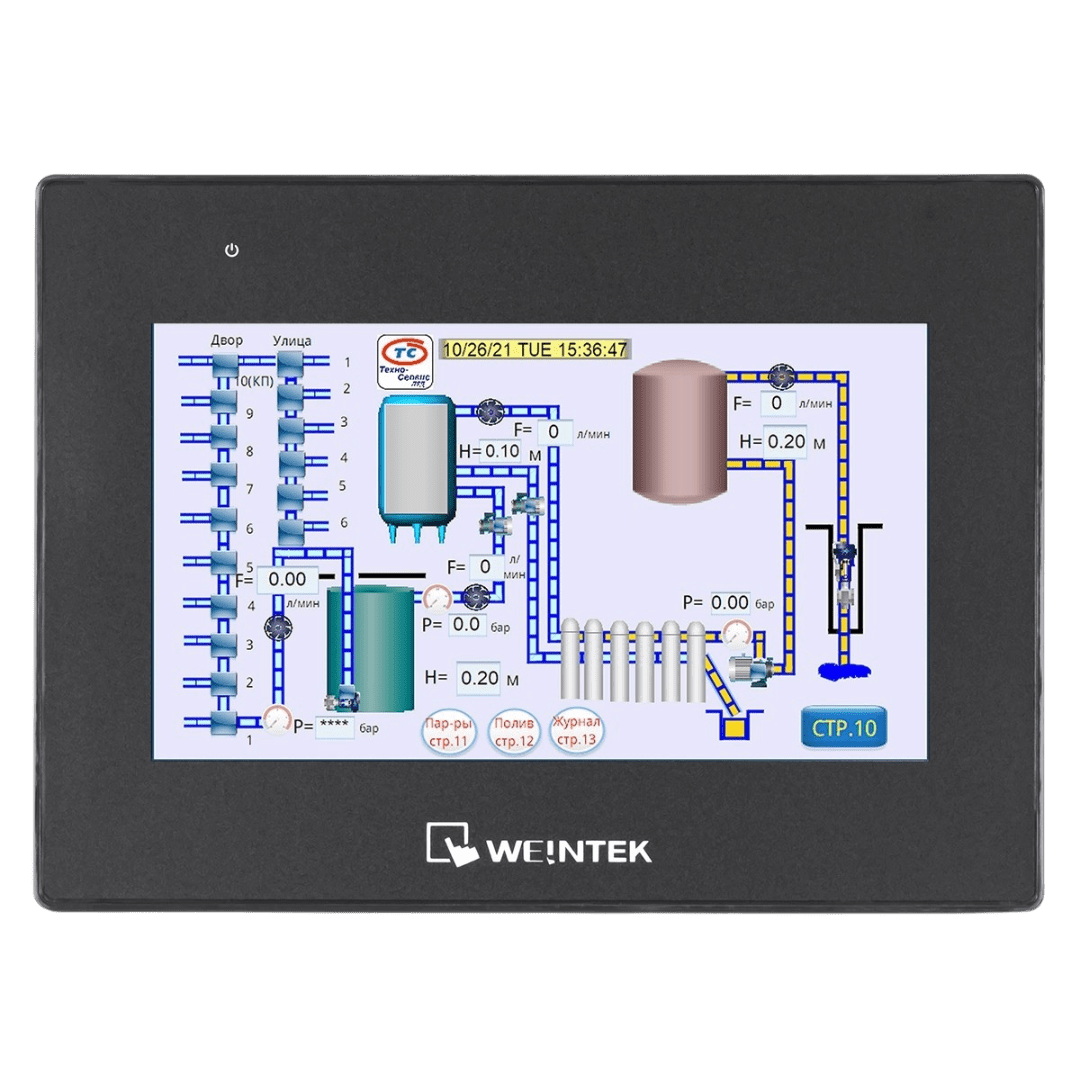

Standard Model

The Weintek standard model of HMI (Human Machine Interface) provide an operational performance. It typically features a high-resolution, full-color touchscreen, support for multiple communication protocols, and powerful configuration software. With I/O capabilities, it allows for seamless integration with various PLCs and industry-standard devices, bolstering its utility in diverse automation tasks. These HMIs are also known for their high durability, wide operating temperature ranges, and ability to withstand challenging industrial environments.

View Broucher

Advance Model

The Weintek advanced model of HMI stands out for its high-resolution, full-color touchscreen displays that ensure clear visibility and responsive control. It is equipped with powerful CPUs for fast processing, abundant connectivity options including Ethernet and serial ports, and robust data storage capabilities. It provides seamless integration with PLCs and other automation devices, making it a versatile choice for complex industrial automation systems. They feature rugged construction for durability in harsh environments.

View Broucher