INTERESTED IN FINDING OUT MORE?

Consult with our experts now

Advanced solutions for the industry’s premier brands

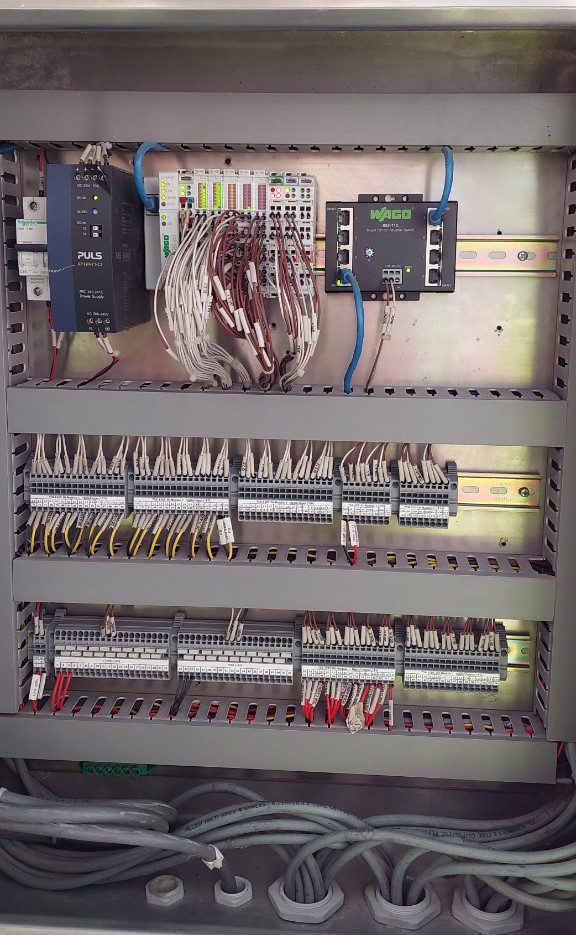

PLC Programming:

PLC programming is the process of creating and maintaining program code for programmable logic controllers (PLCs). PLCs are specialized computers that are designed to control industrial processes, such as those in manufacturing plants, power plants, and other industrial facilities. PLC programming is used to create the code that controls the PLC and allows it to interact with other systems, such as sensors and actuators, to monitor and control the process.

Our PLC Programming services include the following:

- Selection and Configuration of the system

We start by building your hardware profile and then work on the logical process and make programs accordingly into our programming software. Selection and Configuration of the processor, communication modules, and all I/O modules are necessary for the system to perform as designed

- Defining Inputs and Outputs I/O’s

Once the program includes all necessary hardware, we must program in scaling for all I/O modules so that each device communicating to the system is doing so with the appropriate units. We have experienced professionals who can accurately depict and utilize the necessary inputs and outputs of each device.

- Manual Mode Device Programming

S.A. Hamid & Co. uses specially created Add-On-Instruction (AOI)s to program manual control of every output device in the system, ensuring flawless control of every different type of device. Customers benefit from the HMI graphics and pop-ups having a tidy appearance and feel, which allows operators flexibility and consistency while carrying out maintenance or troubleshooting on a particular device.

- System Alarm and Status Programming

S.A. Hamid & Co. incorporates thorough device alarms and feedback on every output device to ensure it operates properly. Additionally, we draw on our extensive experience to walk you through each stage of the procedure while precisely reporting system status and alarm events essential to the process.