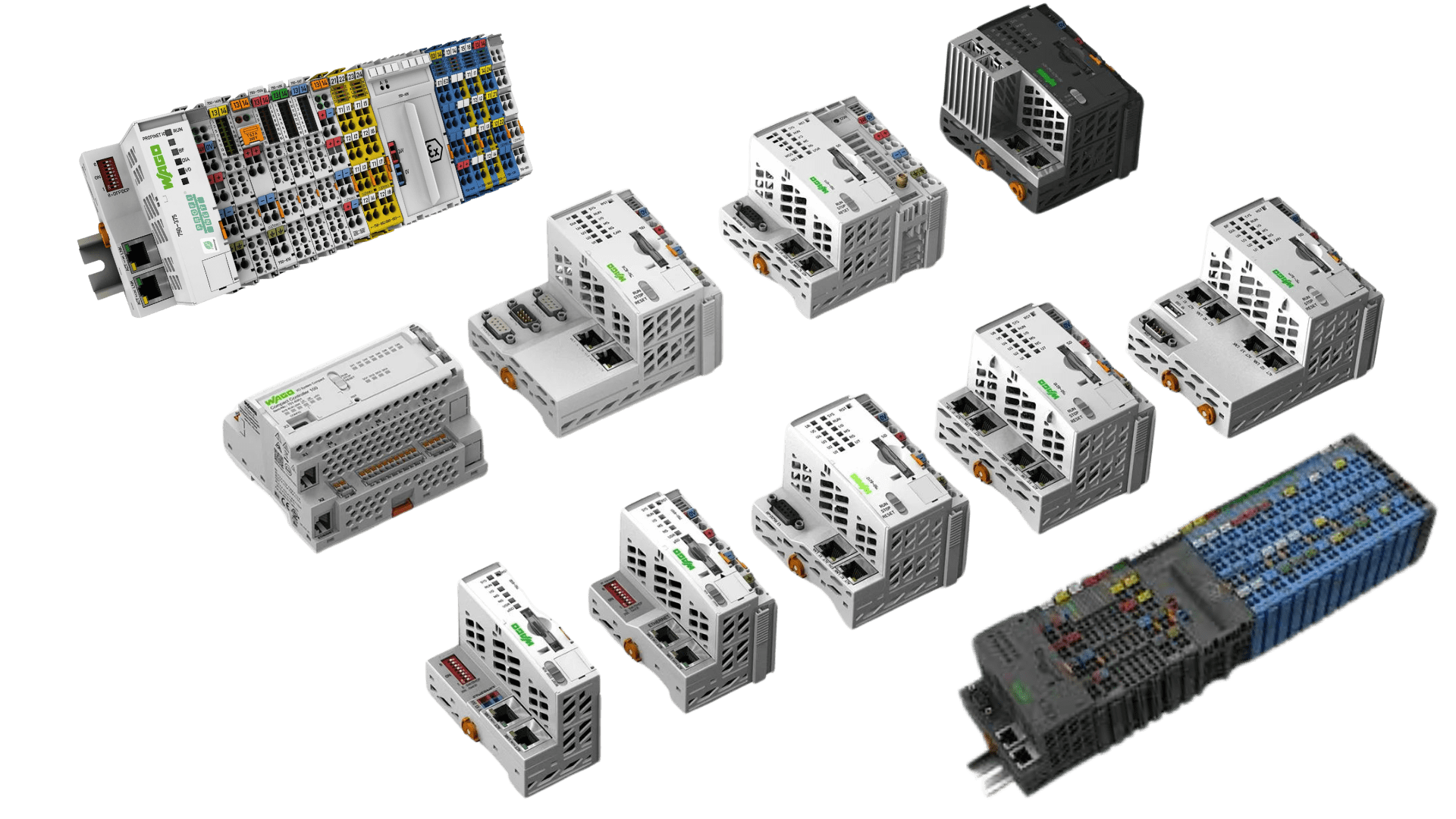

PLC By Wago

WAGO’s programmable logic controllers (PLCs) stand out in the realm of automation solutions, offering a host of benefits that cater to diverse industrial applications. One of the primary advantages lies in their programmability via CODESYS per IEC 61131-1, a widely recognized standard in the field. This compatibility ensures seamless integration and ease of programming, empowering users to efficiently design and implement automation processes. WAGO’s PLCs represent a cost-effective automation solution characterized by top performance, energy efficiency, adaptability to extreme conditions, and seamless integration with the WAGO I/O System 750. These features collectively contribute to enhanced productivity, reliability, and safety across a wide range of industrial settings.

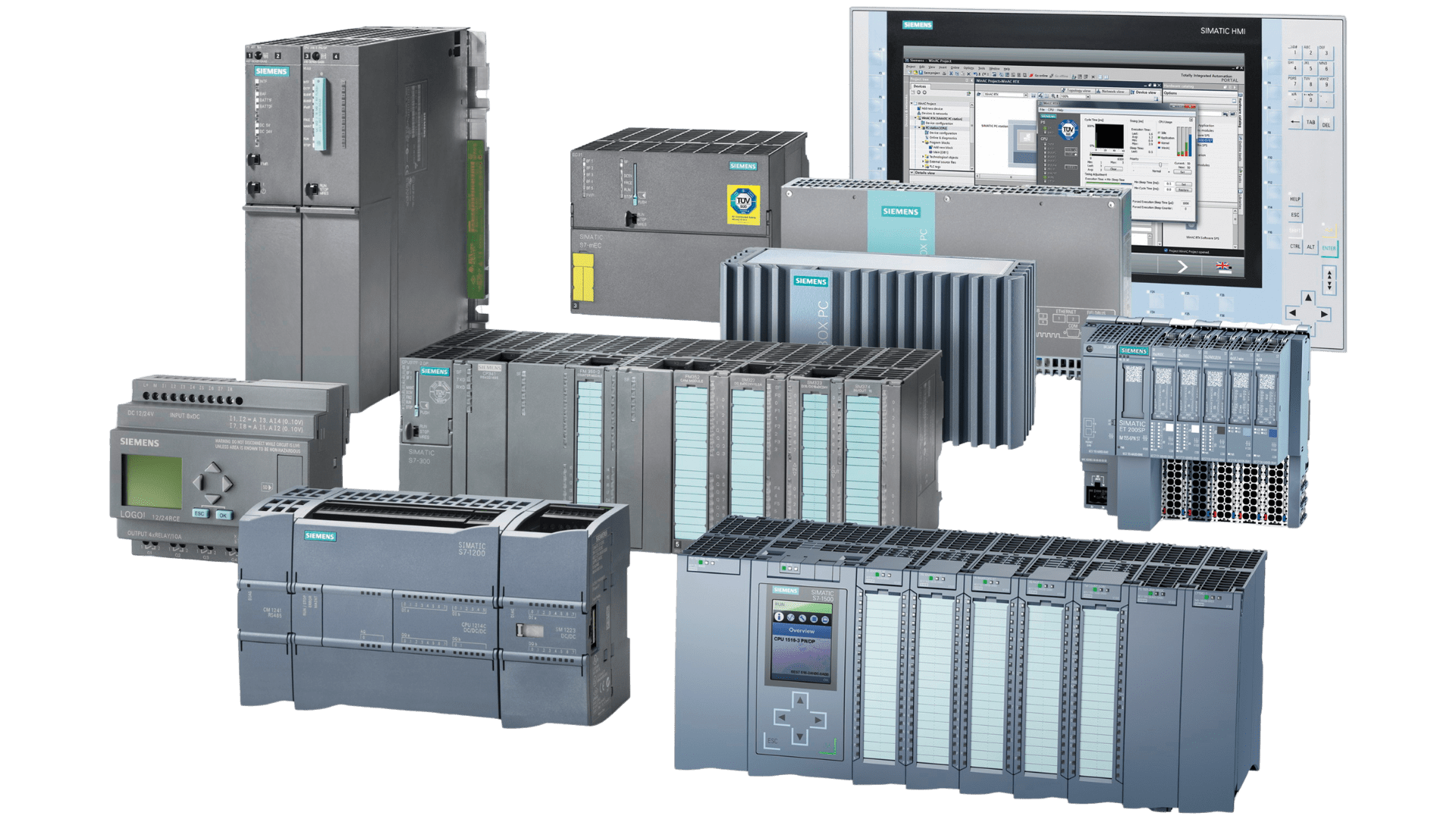

PLC By Siemens

Siemens PLCs, renowned for their reliability and efficiency, cater to a wide array of industrial automation needs across various sectors, including manufacturing, energy, and infrastructure. Their product range spans from the compact S7-1200 series, ideal for small-scale applications, to the advanced S7-1500 series, designed for complex and demanding processes. The S7-300 and S7-400 series occupy the middle ground, offering a balance of performance and flexibility for a broad spectrum of automation tasks. Siemens PLCs stand out for their seamless integration with other Siemens automation products, robust security features, and innovative engineering software, such as TIA Portal, enhancing productivity and operational efficiency. Their adaptability, coupled with extensive diagnostics and communication capabilities, makes Siemens PLCs a cornerstone of modern industrial automation solutions.

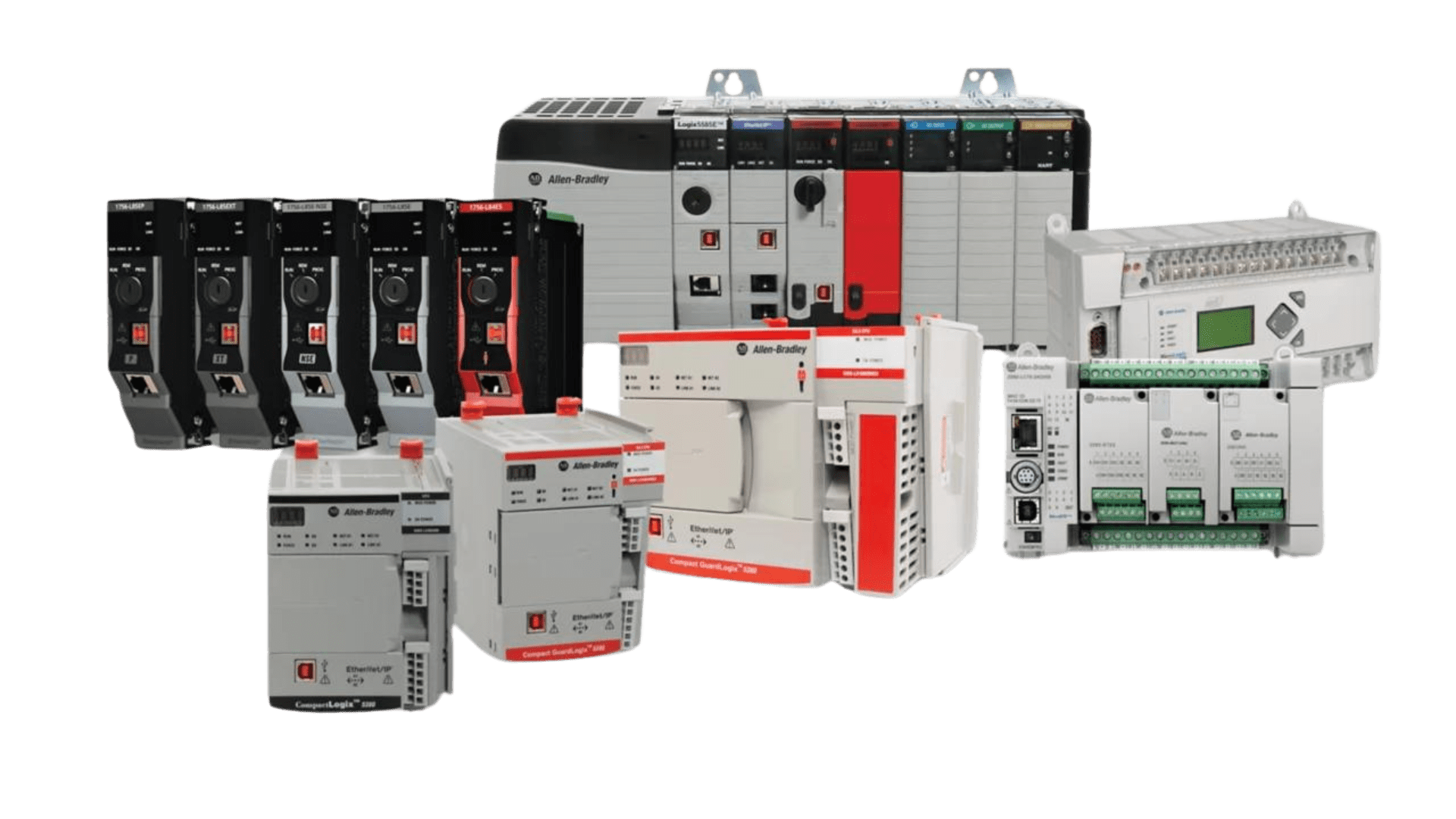

PLC By Allen Bradley

Allen‑Bradley control systems have evolved significantly since the inception of the original programmable logic controller (PLC) in the 1970s. Today, our offerings extend to scalable, multi-disciplined programmable automation controllers (PACs) that cater to a wide range of application requirements, from the complex to the simple. Our focus on controllers and I/O, combined with extensive attachment portfolios, enables the creation of smart, productive, and secure Integrated Architecture® systems across various domains including discrete, process, motion, and safety applications. Whether your needs involve intricate control solutions or straightforward applications, Allen‑Bradley® ensures comprehensive coverage to meet your automation requirements effectively.

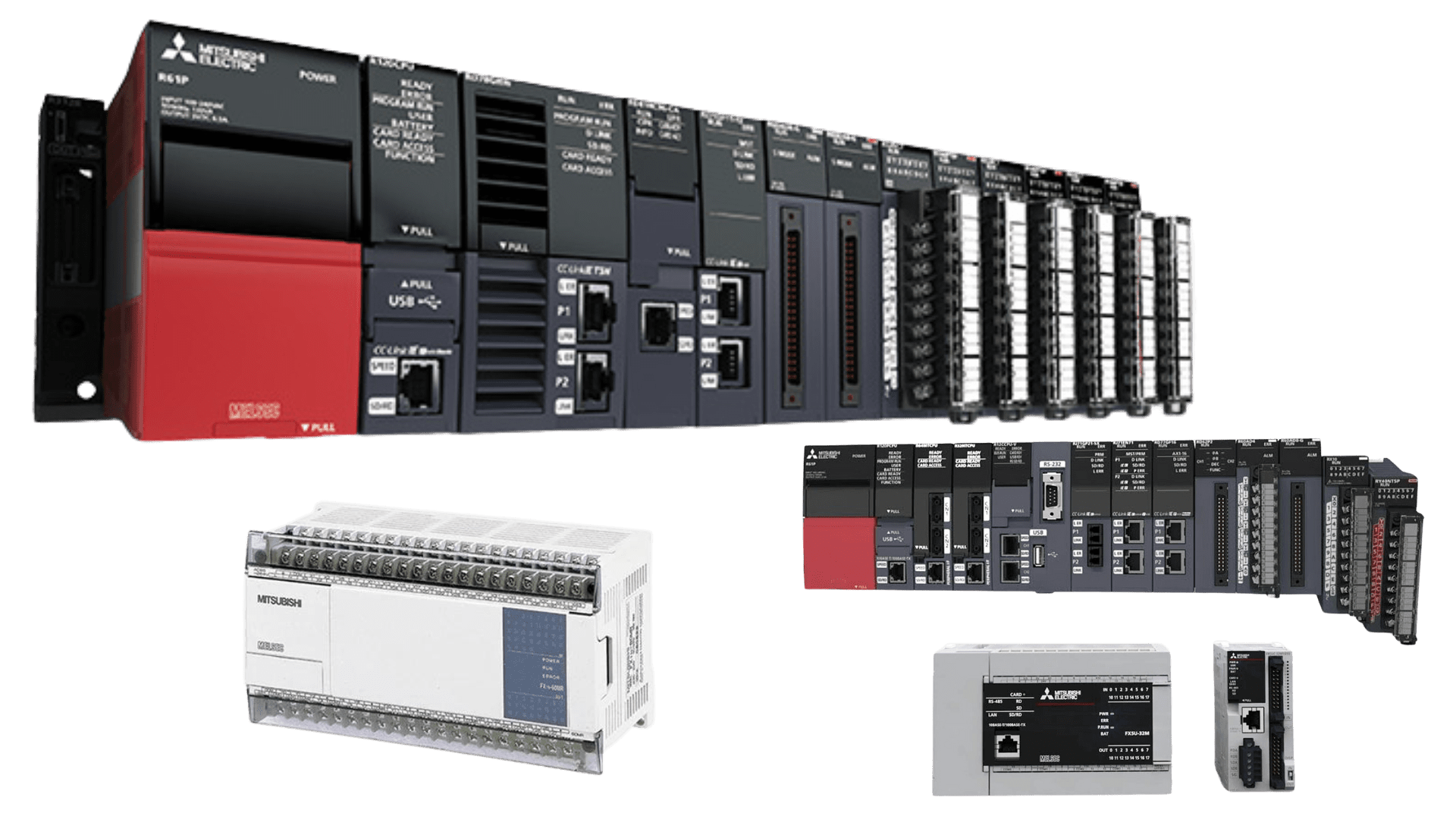

PLC By Mitsubishi Electric

Mitsubishi Electric introduces a comprehensive lineup of programmable automation controllers (PACs) designed to revolutionize industrial automation. At the fore front is the MELSEC iQ-R Series, boasting a groundbreaking high-speed system bus that significantly enhances productivity by delivering advanced performance and functionality. Pioneering the multiple CPU architecture, the MELSEC-Q Series offers a wide array of CPUs, enabling efficient control of multiple operations and thereby enhancing overall production system performance and scalability. The MELSEC-L Series stands out as a baseless, highly scalable controller tailored for space-constrained applications. Its CPU head integrates various I/O functionalities, achieving exceptional cost-effectiveness without compromising performance within a compact form factor. MELSEC iQ-F Series emerges as a powerhouse in drive control, offering superior performance and a rich assortment of integrated functions in a compact-class controller.

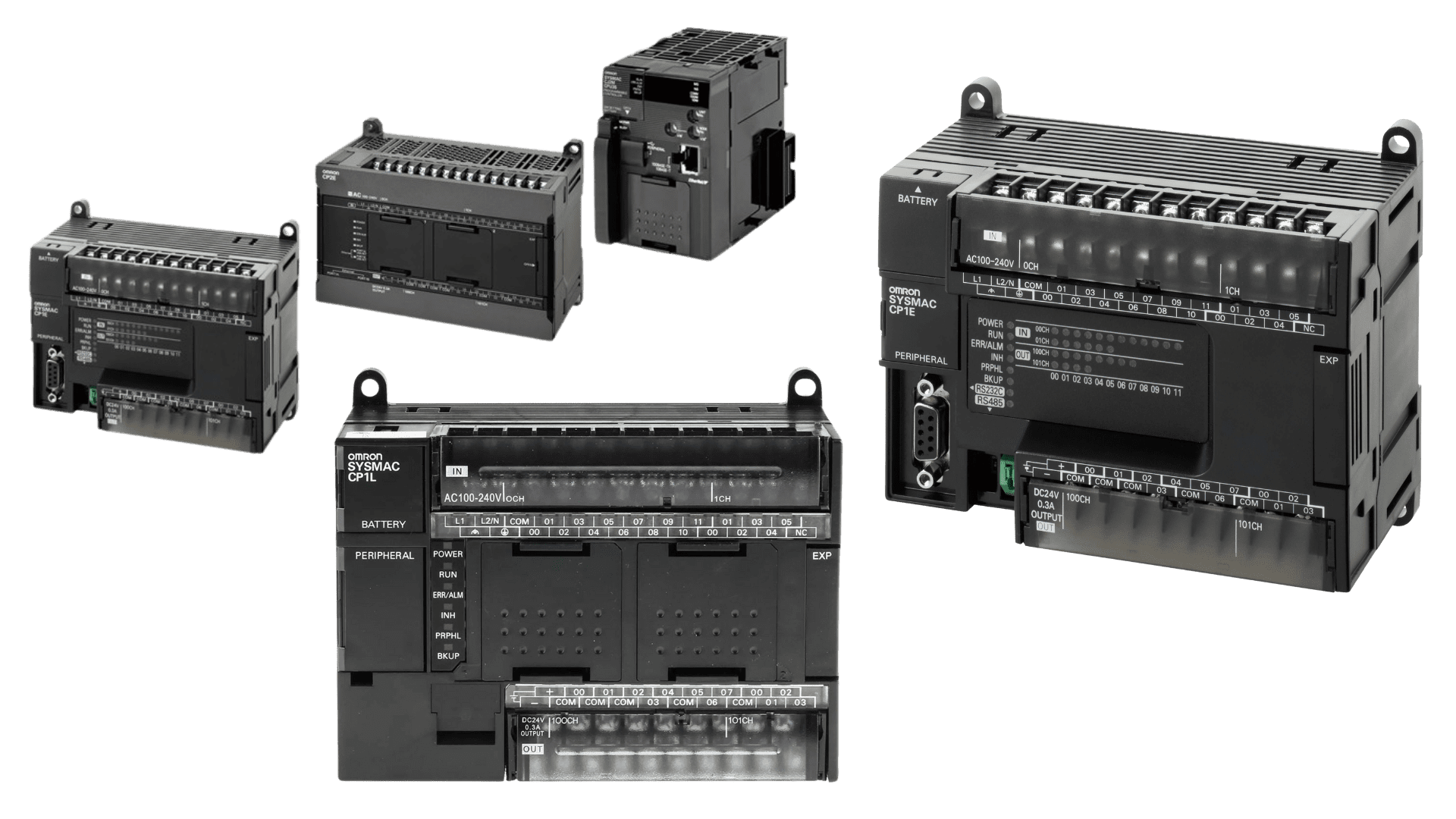

PLC By Omron

Omron Corporation stands out as a prominent manufacturer of compact micro-range Programmable Logic Controllers (PLCs) for the automation industry. Their product line offers scalability and high performance, making them suitable for stand-alone machines or integration into larger control systems. PLCs are specialized digital computers designed to robustly manage industrial processes, machine systems, or entire production lines. By executing programmed sequences of instructions and conditions, PLCs control machinery and processes, facilitating precise control over positions, continuous quantities, and speeds. Additionally, PLCs facilitate seamless data exchange between devices, enhancing overall system efficiency. They serve as the central control unit in various industrial automation setups, providing reliable control, fault diagnosis capabilities, and ease of programming.Common applications of PLCs include traffic light systems, automatic doors, elevators, amusement rides, and automatic car washes, where replace manual control with efficient processes.

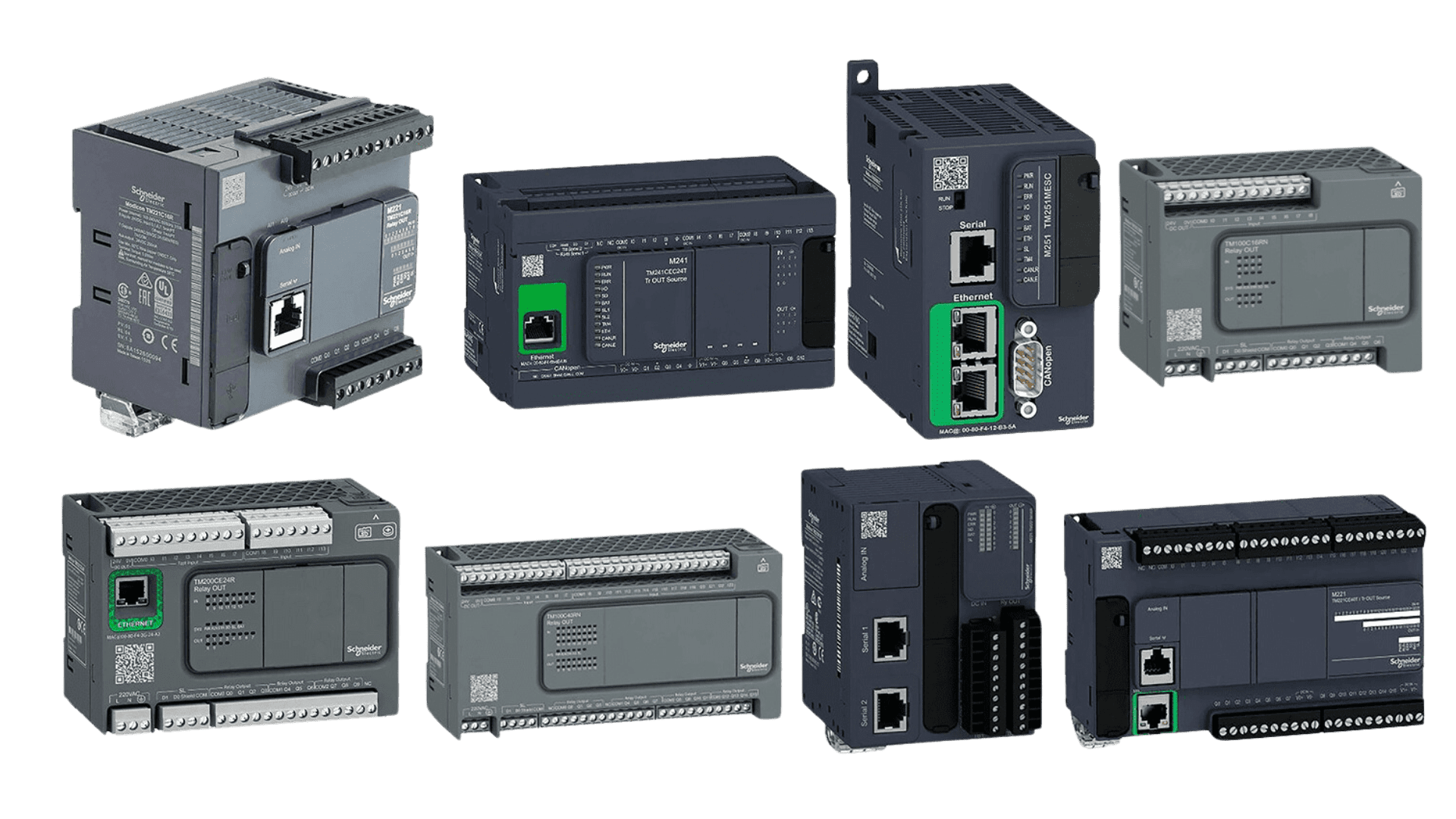

PLC By Schneider Elecictric

A PLC (Programmable Logic Controller) is a computing device, like your PC or smart phone, that is used to monitor and control the operation of machines and equipment used in utilities and industry. The PLC monitors inputs (i.e. voltages), and an internal computer makes decisions using logic to send commands to outputs (i.e. relays), that in turn control the machines and equipment. A programmable PLC is one that can be made to do a specific task. All PLCs today are programmable, but they range from basic to complex types. PLCs can also be monitored by other computer applications like SCADA or cloud-based apps. Recent advances in PLCs allow for much greater connectivity and integration with a centralized management system. Our next-generation PLCs offer built-in cybersecurity, connectivity to multiple devices or the cloud, and processing power needed to handle big data analysis.

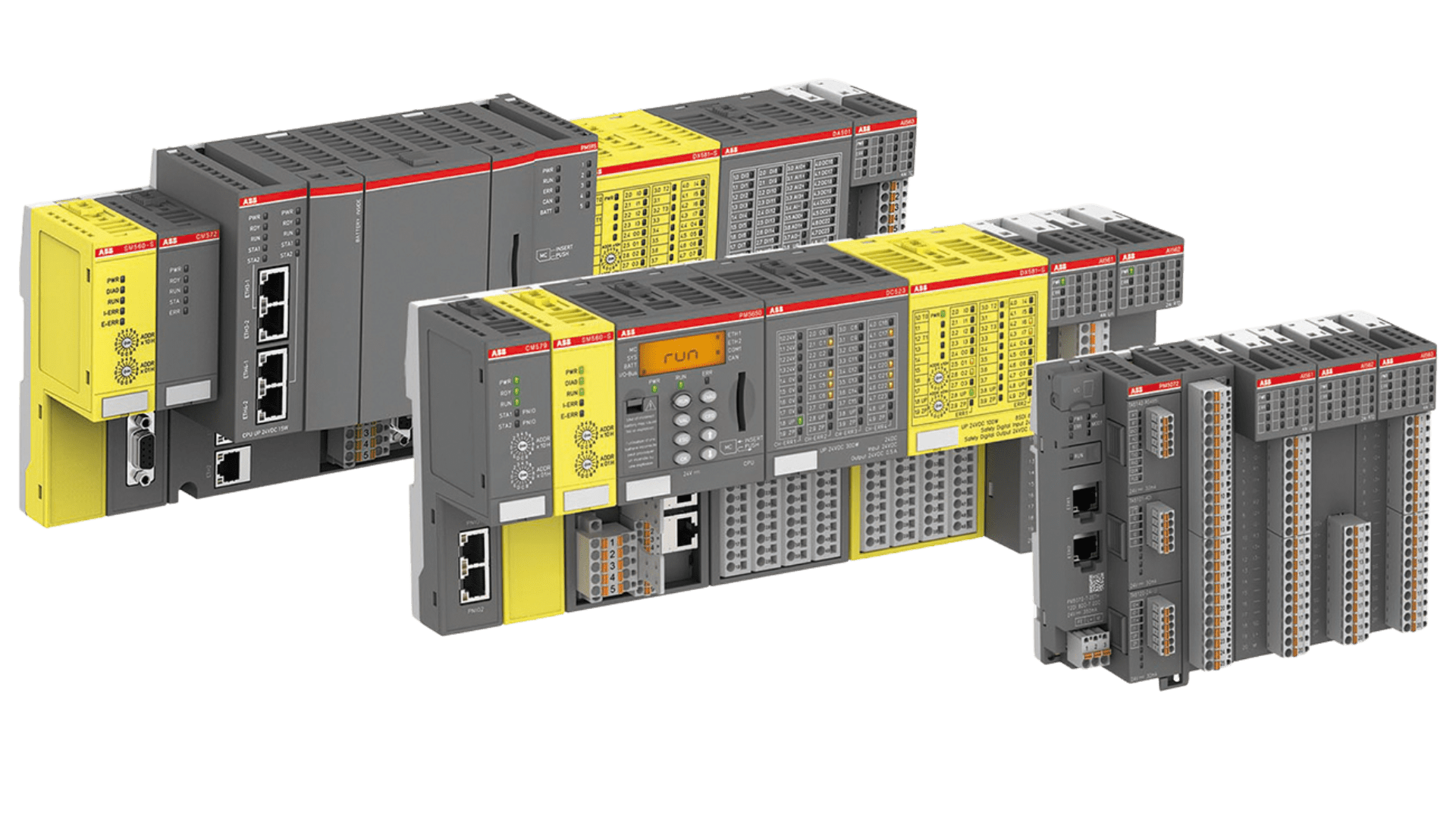

PLC By ABB

ABB is renowned for its comprehensive PLC and HMI control solutions, notably the AC500 PLC platform, acclaimed for its high performance and reliability. The Automation Builder software suite integrates configuration, programming, debugging, and maintenance tools into a single intuitive interface, reducing software-related costs, a significant expense in industrial automation. With the AC500-eCo, AC500, AC500-XC, and AC500-S scalable PLC ranges, ABB caters to applications of varying sizes and complexities. The AC500 PLC platform boasts different performance levels, making it an ideal choice for demanding environments and specialized applications such as motion control and safety solutions. It ensures interoperability and compatibility across hardware and software, from compact to high-end and safety PLCs. ABB’s CP600-eCo, CP600, and CP600-Pro control panels offer extensive features and functionalities. ABB control panels stand out for their durability and ease of use, consolidating essential production and machine information into a single touchpoint for streamlined operability.

PLC By Eaton

Eaton Programmable Logic Controllers (PLCs) are indispensable components of automated processes, operating as solid-state electronic devices with programmable logic functions. Through programming software, logic functions are embedded into their memory, essentially serving as the central “brains” behind automated operations. They excel in monitoring various inputs from sensors such as pressure sensors, temperature sensors, limit switches, auxiliary contacts, and pilot devices. These inputs provide crucial data, including on/off statuses, voltage values ranging from 0 to 10V, or amperage values up to 24mA. PLCs execute programmed instructions, thereby regulating outputs such as motor activation, pilot light illumination, or conveyor speed adjustment. Flexibility is a key feature, as PLCs can accommodate multiple input/output (I/O) configurations, adapting to diverse industrial machinery and processes. Eaton systematic scan cycle ensures prompt and accurate response to changing conditions, making them indispensable in modern industrial automation systems.