Variable frequency drives (VFDs) connect to a motor’s electrical supply and vary the frequency of the electricity powering the motor. This controls the motor’s performance and reduces the amount of energy the motor consumes. VFDs work with three-phase vector (inverter) motors in constant-torque and variable-torque applications. Constant-torque applications maintain the same torque throughout their speed range, like a conveyor belt. Variable-torque applications will experience surges and lulls in the load, such as fans, blowers, and pumps. VFDs have either an open or enclosed design. Open VFDs are standalone devices that mount in electrical cabinets or directly on the machine frame. Enclosed VFDs are housed in a panel with additional controls that monitor the VFD and minimize motor downtime. VFDs are used in a wide range of industrial processes, water management, and HVAC applications.

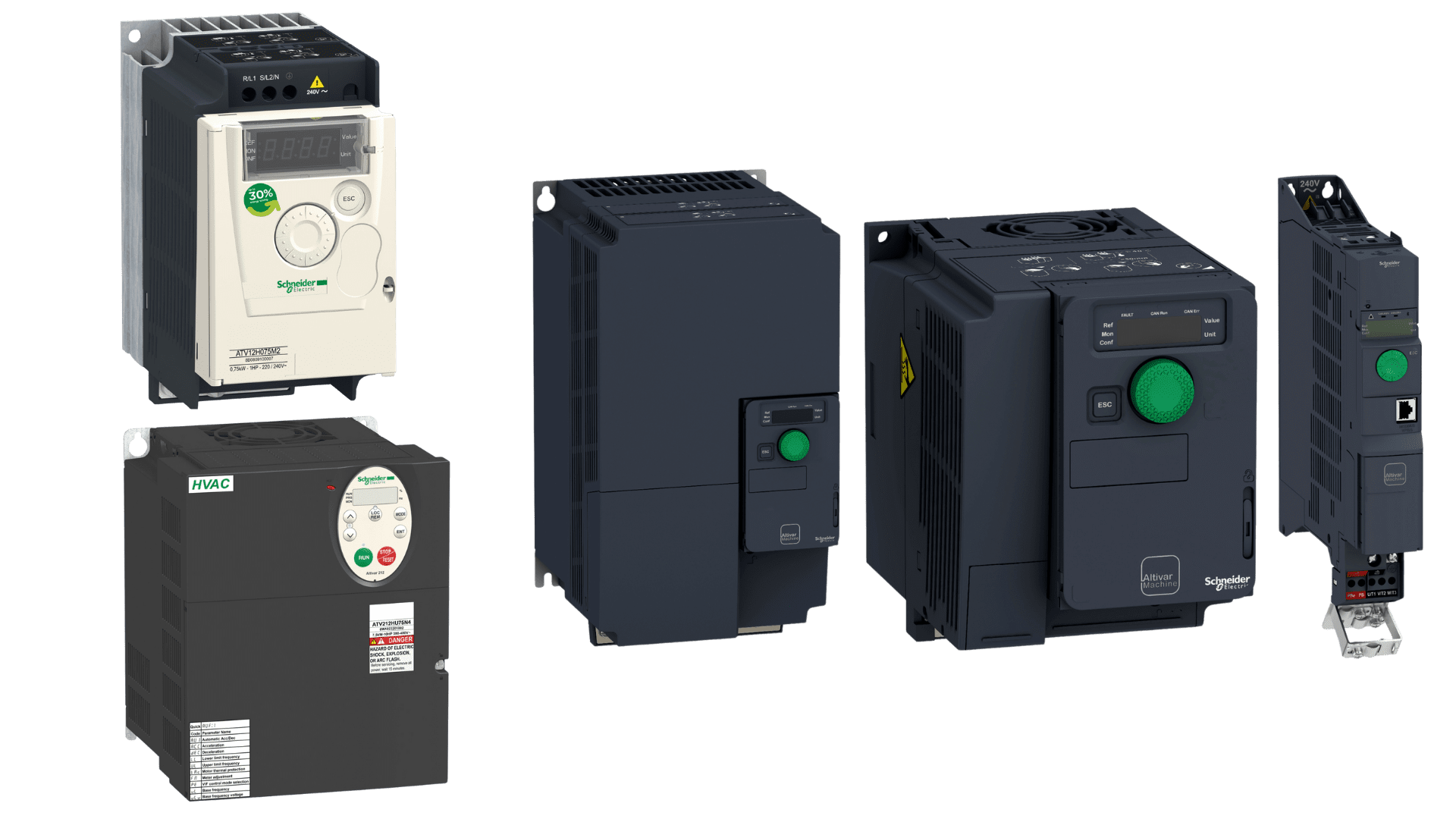

Schneider Altivar Atv320

Schneider Altivar Atv600

Schneider Altivar Atv340

Schneider Altivar Atv12

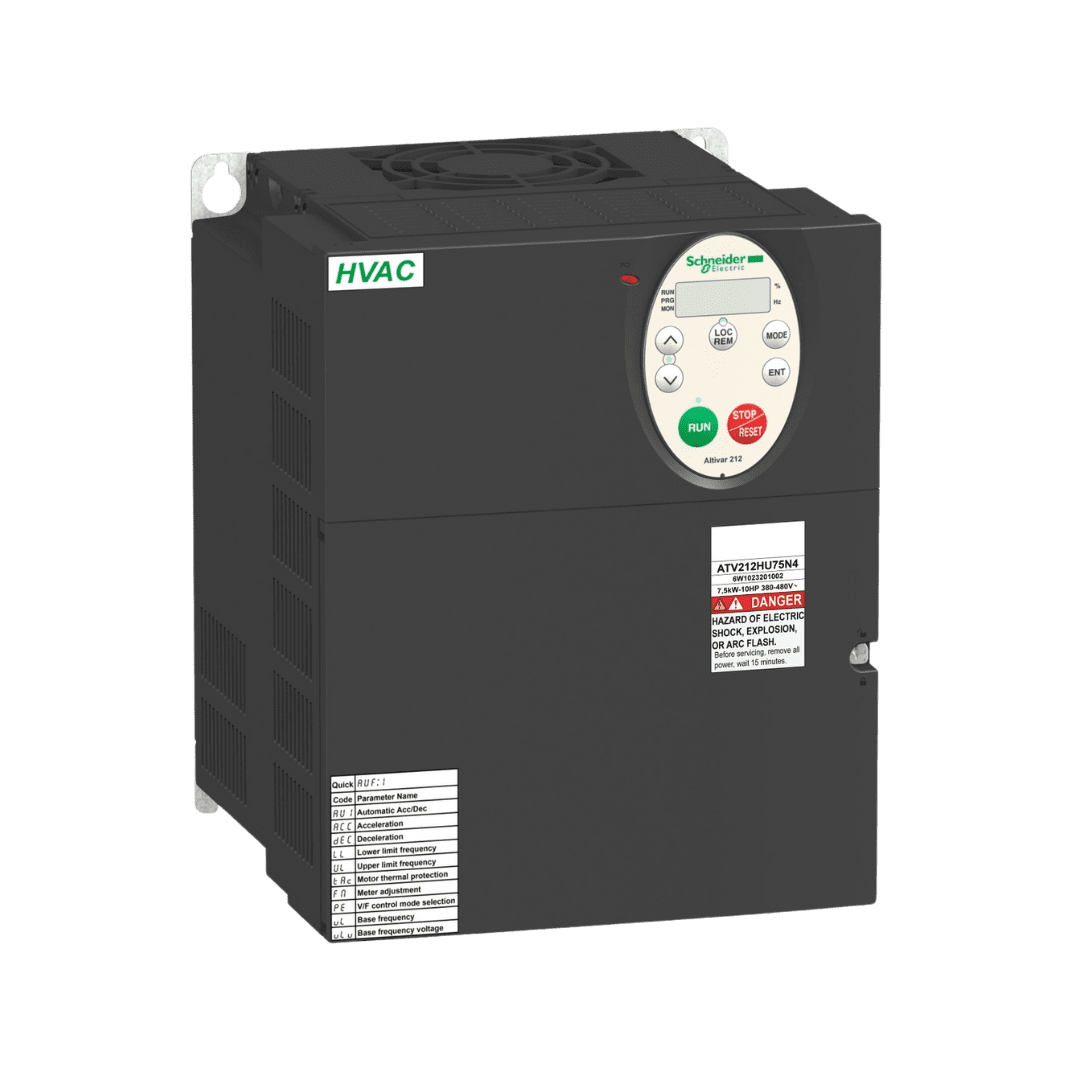

Schneider Altivar Atv212